Fixture test

There's no electronics without mechanics: everything starts with a printed circuit board and ends with a connector. To test a board, you need electrical connections between measuring instruments and equipotentials. ATE provides turnkey solutions that include hardware and software.

All the solutions we offer comply with standards, and are designed to ensure efficiency, productivity and ergonomics for the user.

We pay particular attention to tool handling, looking for solutions to reduce weight or promote the use of a manipulator.

Test benches for electronic boards

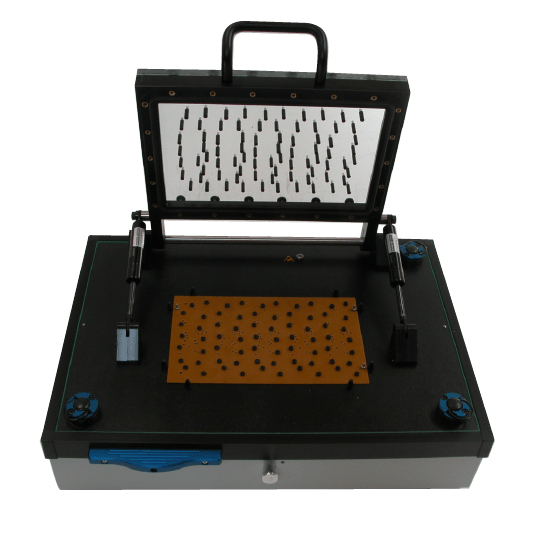

Bed of nails is used in industrial electronics to analyze, control and program a printed circuit board or equipped card. It consists of a tray on which spring-loaded test pins are placed. These are inserted into a sleeve to be replaced in the event of failure or wear.

Electrical continuity with the test fixture is ensured by a "wrapping" wire connection or a specific printed circuit (wireless fixture).

It all starts with the installation of the socket in a drilled epoxy plate.

Operating principle of the test fixture

The electronic board to be tested is placed on the nail board. The nails are then brought into contact with the board's test pads using a mechanical device, or with the aid of atmospheric pressure using a vacuum bell.

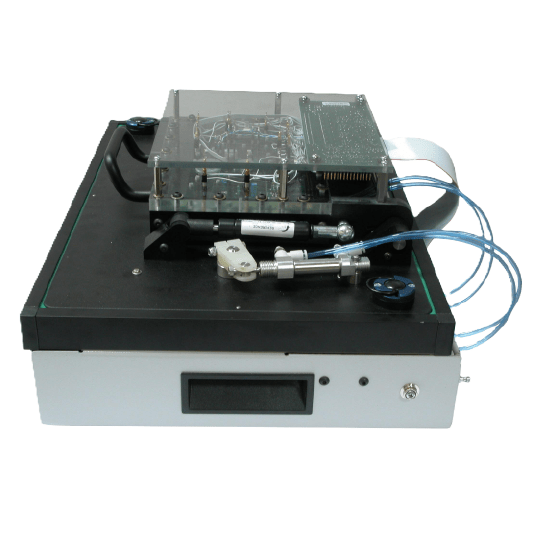

The test system then generates electrical signals which are applied through the device to the various equipotentials on the board. Electrical measurements are then taken, and the results compared with expected values.

Our two solutions

We have two solutions for ensuring an electrical connection between the thermowell and the test system.

The wrapping

A printed circuit board

Accessories

Some of the functions implemented on electronic boards may need to be interpreted by a sensor or accessory to support the automatic test system.

LED color sensor

Allows color and brightness to be identified directly on the component or through an optical fiber.

Infrared temperature sensor

Allows you to read the temperature of the cards as they come out of the reflow oven, and to rule out non-compliant cards.

Datamatrix sensor

To read the serial number and start the test.

Color sensor

Description

Frequency amplifier

Description

USB bus

USB bus management with automatic tester

Push-button activator

Description

Marking engraver

Description

Framescan probe

Description

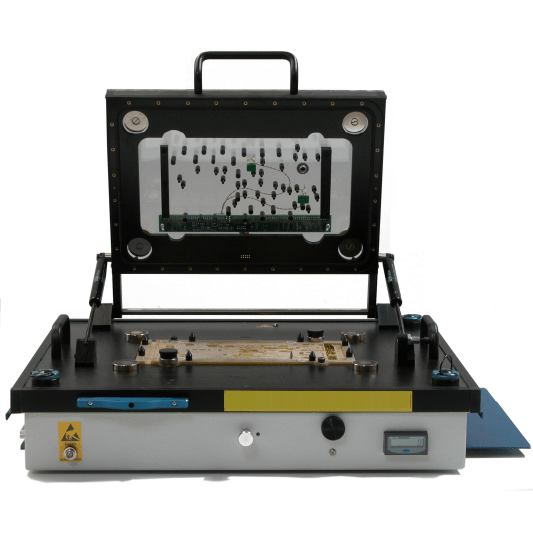

Double-level test fixture

Double level air actuator

Double level magnet actuator